hardness test for steel|how to measure steel hardness : traders There are several frequently used methods to measure the hardness of metals, including: 1 Rockwell Hardness. The Rockwell hardness test measures the depth of penetra-tion of an . Perguntas Frequentes. 1. Associei-me, mas não recebi a Carteirinha da Appai. O que pode ter acontecido? A carteirinha associativa da Appai serve para a constatação da filiação .

{plog:ftitle_list}

WEB8 de jun. de 2022 · Then save $10/month for 3 months. Dinheiro infinito no FS22, Dinheiro Fácil para o Farming 22Link para os nosso grupos:🔵 Grupo no Facebook: http://bit.ly/OsKongs🔵 Grupo .

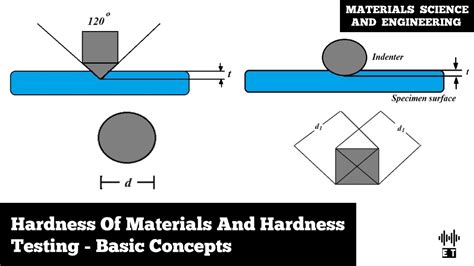

types of hardness testing methods

Rigorous metal hardness testing involves using a probe to indent or penetrate the surface of a material, with standard tests using different probe shapes and formulas to derive a numeric value. Various hardness testing .There are several frequently used methods to measure the hardness of metals, including: 1 Rockwell Hardness. The Rockwell hardness test measures the depth of penetra-tion of an .Hardness test methods in the macro range include Brinell, Vickers and Rockwell. Hardness testing in the low-load range applies when the test load falls between an interval of 0.2 kgf and 5 kgf (test load ≥ 0.2 kgf and < 5 kgf). The most .The hardness test method according to Vickers is described in standards ISO 6507 (Metallic materials – Vickers hardness test – Part 1: Test method) and ASTM E384 (Standard Test Method for Microindentation Hardness (1gf - 200 .

Knowledge and insight into materialographic hardness testing – including how to test metallic and other materials, and the definitions, applications and conclusions of different hardness tests – . Related reading: Metal Hardness Comparison Chart: HV, HB, HRC Commonly Used Hardness Brinell Hardness. The Brinell hardness test uses a ball made of hardened steel or a hard alloy with a diameter of D as the . Hardness testing is a vital process in many industries. Our guide explains everything you need to know about this crucial technique. . Indenter: 120 diamond cone or hardened steel ball. Rockwell hardness definition: .

Brinell Hardness Test; This hardness test is suitable for ferrous and non-ferrous metals, including hardened stainless steel materials. The Brinell hardness test uses a load range of between 500 to 3,000kgf to cause an indentation using a ball indenter on a smooth surface. Additionally, the ball indenter is often 10mm in diameter and made of . Brinell Hardness Test. The Brinell hardness test entails measuring the diameter of indentation caused by a constant concentrated force applied by a steel or carbide spherical indenter on a test specimen. The steel ball indenter is first placed in contact with the material before a constant force is applied and maintained for a 10 to 15 second duration, known as the .The Vickers hardness test is ideal for testing of all metals and is therefore the method with the widest range of application. The hardness test method according to Vickers is described in standards ISO 6507 (Metallic materials – Vickers hardness test – Part 1: Test method) and ASTM E384 (Standard Test Method for Microindentation Hardness (1gf - 200 gf) of Materials .The Brinell hardness test is commonly used to determine the hardness of materials like metals and alloys. . Steel Hardness versus Strength; Brinell Vickers Rockwell Equivalent Rm; Impression Diameter (mm) Hardness HB. Hardness HV. Hardness B. Hardness C (ton f /in 2) (kg f /mm 2) (N/mm 2) 2.50: 601:

The Brinell method is suitable for hardness testing of soft metals (light metals, lead, tin) as well as hard metals, such as steel and iron.. Brinell testing of a material with different ball diameters and test forces must be conducted within the same force-diameter index („Brinell test procedure“) in order to enable direct comparison of the measured hardness values. Steel - Testing, Properties, Manufacturing: The testing of steel’s properties often begins with checking hardness. This is measured by pressing a diamond pyramid or a hard steel ball into the steel at a specific load. The Vickers Diamond Pyramid Hardness tester, which measures the DPH mentioned above, uses an indenter with an included angle of 136° .The indenter used in the Brinell hardness test is usually a hardened steel or carbide ball. There are four sizes of the indenter used for the Brinell hardness test. They are 1 mm, 2.5 mm, 5 mm, and 10 mm in size. The choice of diameter depends on the hardness of the material being tested.

In the Brinell test, a steel ball of 10 mm diameter is used as an indenter to create an impression on the test piece to calculate its Brinell hardness number. . Mohs hardness test uses 10 reference materials of varying hardness as the scale for the test. The softest material used is talc (value=1) and the hardest material is diamond (value=10 In Brinell hardness test, a steel ball of diameter (D) is forced . under a load (F) on to a surface of the test sp ecimen. Mean diameter (d) of indentation is .

The specific size, shape, and location requirements of the hardness test determine the use of the Vickers method. One of the key advantages of the Vickers Hardness test is its versatility, as it can be applied to a wide range of materials and properties. Vickers Macro Hardness testing standards we work with: BS EN ISO 6507-1:2018 (HV1, HV5, HV10)

The best hardness test method and corresponding load depend on the material to be tested, the component shape, applica- . Steel/Iron Light Metal Copper Aluminium Light Metal Copper Aluminium Light Metal Light Metal Lead/Tin *Recommended hardness range according to EN ISO 6506-4, table 2.

In America, the Brinell test using a 100 mm diameter indentor with a load of 3000 Kg is used for hardness testing on steel & iron casting while the aluminum load used is 1500 Kg. Soft materials such as copper and its alloys- Brass & bronze are tested using a 5 -10 millimeters diameter indentor with a 500 Kg load.

3. Hardness Testing of Stainless Steel Pipes. Hardness testing is a critical quality control measure for stainless steel pipes, encompassing both welded and cold-drawn varieties. The testing methodology varies based on .Mohs hardness test: When conducting the test, place the unknown specimen on a table top and firmly hold it in place with one hand. Then place a point of the reference specimen against a flat, unmarked surface of the unknown .Rockwell Hardness Testing Reference Guide Newage Hardness Testers Selection Guide Rockwell Hardness Testing Reference Guide ASTM E18 contains a listing of all regular Rockwell scales and typical materials for which . Common hardness testing methods are introduced below. Rockwell Hardness. This method tests the hardness of steel parts by applying loads to parts via either a tungsten carbide ball or a spheroconical diamond indenter. A part’s testing surface and seating surface must be properly prepared prior to testing.

The connection between hardness and carbon content is clearly visible in the example below: the higher the carbon content, the higher also the HRC of various types of White Steel: White Steel 1 / 63 HRC / C = 1.25-1.35 % White Steel 2 / 61-62 HRC / C = 1.05-1.15 % White Steel 3 / 60 HRC / C = 0.80-0.90 % Measuring hardness There are several .

steel hardness testing methods

The test provides numerical results to quantify the hardness of a material, which is expressed by the Brinell hardness number – HB. The Brinell hardness number is designated by the most commonly used test standards (ASTM E10-14[2] and ISO 6506–1:2005) as HBW (H from hardness, B from brinell and W from the material of the indenter, tungsten . In Rockwell hardness testing, HRA, HRB, and HRC represent three different scales: Scale A, Scale B, and Scale C. The Rockwell test is a common indentation hardness test. All three scales begin with an initial pressure of 98.07N (10kgf), and the hardness value is calculated based on the depth of indentation.

In the Rockwell hardness test, a differential-depth method, the residual depth of the indent made by the indenter, is measured.In contrast, the size of the indentation is measured in the Brinell, Vickers and Knoop optical test methods.. The deeper a defined indenter penetrates the surface of a specimen with a specified test load, the softer the material that is being tested.Brinell hardness of Mild Steel . For softer materials, a smaller force is used; for harder materials, a tungsten carbide ball is substituted for the steel ball. The test provides numerical results to quantify the hardness of a material, which is expressed by the Brinell hardness number – HB. The Brinell hardness number is designated by the .A standardized test procedure used to determine the hardenability of steel, the Jominy test (End Quench Test) can be performed using either the Vickers or Rockwell hardness test method. When selecting which to use, you should consider relevant standards, as well as the usual criteria when choosing between different types of hardness test.Testing the hardness of steels can be used an indication of how easily they can be manipulated, (formed, machined etc.), and how they will perform mechanically. Hardness test methods. Common tests for hardness in metals involve measuring the resistance to indentation by a hardened steel or diamond ball, cone or pyramid.

There are a variety of hardness test methods in common use (e.g. Brinell, Knoop, Vickers and Rockwell). . For softer materials, a smaller force is used; for harder materials, a tungsten carbide ball is substituted for the steel ball. The test provides numerical results to quantify the hardness of a material, .The test provides numerical results to quantify the hardness of a material, which is expressed by the Brinell hardness number – HB. The Brinell hardness number is designated by the most commonly used test standards (ASTM E10-14[2] and ISO 6506–1:2005) as HBW (H from hardness, B from brinell and W from the material of the indenter, tungsten .

Package Vertical Steam Boiler —50L traders

webJade Canhão. @jadecanhao ‧ 2.29K subscribers ‧ 6 videos. Olá! Sou a Jade Canhão e tenho 20 anos. instagram.com/jadecanhao and 1 more link. 3:10:20.

hardness test for steel|how to measure steel hardness